Pittcon 2018: Top New Products

As part of our regular Pittcon issue, IBO recognizes three new products (introduced or shipping as of the beginning of the year) from the show that demonstrate technical advancement, innovation and a high potential for commercial success. This year’s selections represent a range of approaches to further productivity gains in the lab; specifically, faster and easier workflows in the first case, dual-analysis capabilities on one instrument in the second case, and, in the third case, the ability to test a smaller size of analytes.

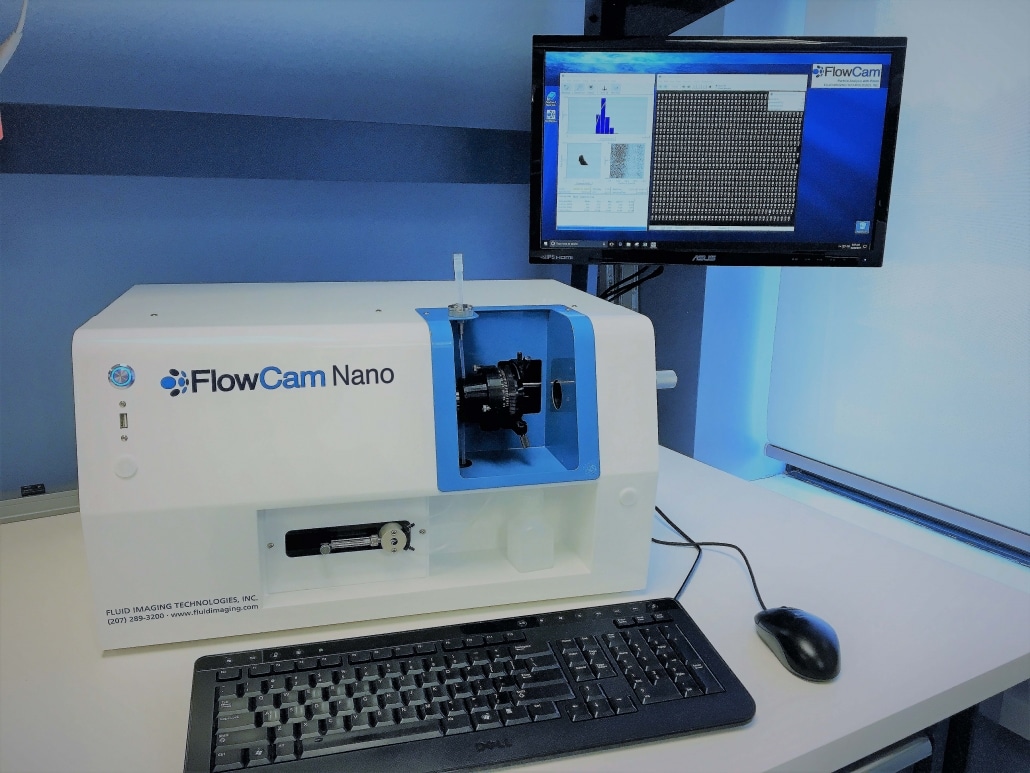

CEM’s EDGE

The first choice for IBO’s top Pittcon product introduction is CEM’s EDGE (Energized Dispersive Guided Extraction) system for molecular analysis. The system presents a new automated sample preparation solution for LC or GC analysis, addressing sample preparation challenges, such as speed and cost, in a system that integrates automation and a simple user work process.

The EDGE is designed to provide a faster extraction sample preparation solution, requiring less solvent and producing less waste compared to QuEChERS, PSE, soxhlet, automated soxhlet and ultrasonic extraction. It also eliminates the need for different extraction techniques for different sample types. Based on Q-Cup Technology, which combines pressurized fluid extraction and dispersive SPE, run time is five minutes per sample (including filtering, cooling and washing) for up to 30 g. Twelve samples can be processed at a time on one system. The small footprint is attractive for high-throughput labs wanting to use multiple systems.

Click to enlarge

System components for ease of use include a three-piece sample holder; disposable Q-Discs consumables, which in addition to sorbents are also available in other materials, such as C18; a built-in heating method, eliminating the need for external gases or pressure; and self-cleaning. Once loaded, an autosampler transfers the sample holder to a chamber where solvent is added at the top and bottom. The chamber is then heated internally and pressurized, and the sample extracted. The extract is filtered, cooled to room temperature and collected. The holder is removed and the chamber is rinsed.

Applications include pesticide monitoring, fat analysis and phthalate testing. The system is priced at $35,000 and began shipping earlier this year. The company expects to ship over 50 units in the next 3–4 months.

Microtrac’s Sync System

Microtrac’s new Sync system provides two different types of particle measurement in the same system, laser diffraction and image analysis. The instrument is quite notable for having these measurements not merely sequential, but virtually simultaneous at the same point in the path of the dispersed particles. The laser diffraction system uses 3 lasers and 2 detectors to capture information at multiple angle separations, while an LCD white light source provides illumination for a high-speed digital camera recording images at roughly 60 frames per second.

This is rapid enough that multiple images of the same particle are recorded as they pass through the measurement segment, allowing for robust measurements of 3D particle shape. This can be blended with the laser diffraction data to provide a fuller picture of the particles in the sample. These complementary measurements of size and morphology will be a great boon to a broad class of applications, particularly when particles are improperly dispersed or form aggregates–these situations can be picked up immediately from the image data–while the diffraction data is already a well-established standard in the marketplace.

The system covers the particle size range from 0.01 µm to 4,000 µm. At the smaller end, the data is generated primarily by laser diffraction; conversely, for larger particles, image analysis provides better information. The system can handle both wet and dry samples, and converting between sample types is relatively simple. Some of the system components are manufactured by a 3D printing process. Many different industries can benefit from the system, including pharmaceuticals, additives, pigments, ceramics, cement and the growing 3D printing market itself. The Microtrac Sync will be ready for shipment in April with a price point around $60,000.

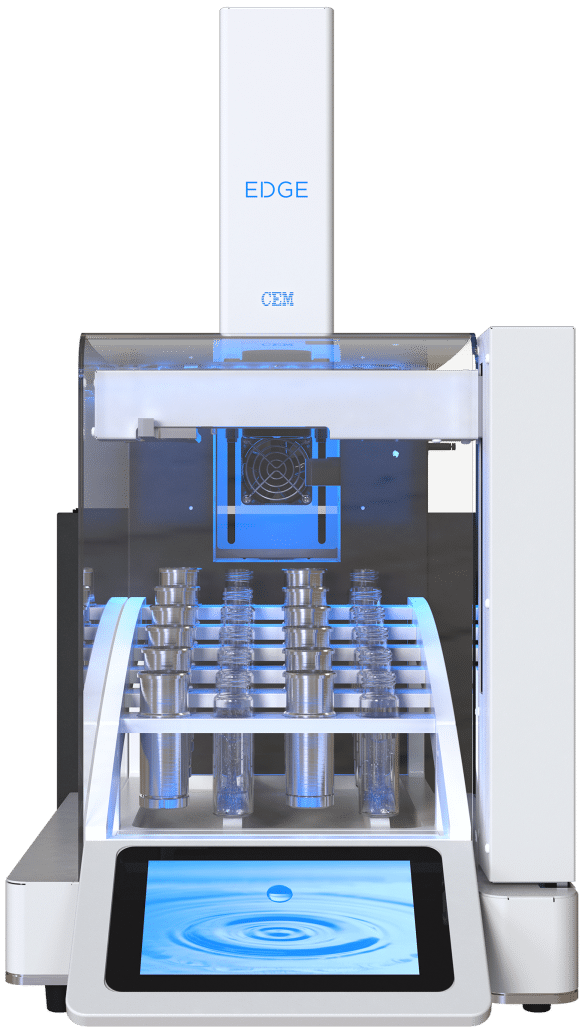

Fluid Imaging Technologies’ FlowCam Nano

Fluid Imaging Technologies’ FlowCam Nano has been selected largely due to its technological innovation. As the first and only flow imaging system for nanoparticles, the FlowCam can detect and produce high-resolution images of 300 nm to 10 µm particles. Similar competitive products typically measure particles down to about a micron in size, so this new product has broken the 1 µm limit and passed into the nanoscale. The system utilizes the company’s oil-immersion microscopy for flow imaging spectroscopy technology to analyze the actual size from the image.

The system can also automatically measure 40 different parameters, including size, count, concentration, grayscale, and other morphological characteristics, in real time. It can be used to image protein agglomerates, silicon oil droplets, glass shards and other opaque/transparent sub-visible particles. Among its drug development applications are the measurement of colloidal stability and its resistance to aggregation, especially in therapeutic protein formulations, lyophilized biologics and injectable drugs. With the addition of FlowCam Nano, the FlowCam product line now has six different models that can analyze particles with a size range of 300 nm–5 mm.