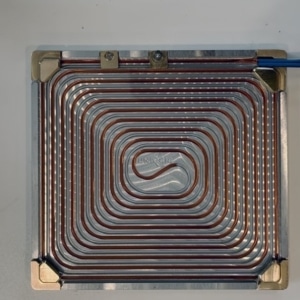

Tube-in-plate reactor for flow chemistry

For synthetic chemistry experiments requiring efficient heat transfer – Uniqsis has introduced a novel Tube-in-plate (TIP) reactor that provides a cost-effective alternative to glass static mixer (GSM) reactor blocks.

For highly exothermic or fast, mixing-dependent reactions. GSM reactor blocks produce an efficient, turbulent mixed reagent stream that is not diffusion dependent. However, while the narrow internal channels / large surface area of GSM reactor blocks provides very efficient heat transfer and mixing they can be prone to blockage.

To address these issues, in applications where static mixing is not a concern, Uniqsis has developed a new TIP reactor using narrow bore, perfluoro polymer tubing embedded in channels cut into an aluminium block. To help stabilise the internal temperature of the TIP reactor, but retain visibility, the tubing is covered with a glass plate. Beneficially the glass cover-plate and tubing can be easily removed, and the tubing replaced – should it become blocked or contaminated.

With an internal volume of 9.5ml – a single layer large format TIP reactor can be used for both photochemistry and conventional thermally mediated reactions.

For reactions where static mixing is not a concern, these TIP reactors offer a cost-effective alternative to ‘large format’ GSMs and are fully compatible with Uniqsis HotChip, ColdChip, PhotoChip and Polar Bear Plus GSM reactor modules.

For further information on Tube-in-plate reactors please visit www.uniqsis.com or contact Uniqsis on +44-1223-942004 / [email protected].

Since 2007, Uniqsis has specialised in the design and supply of mesoscale continuous flow chemistry systems for a wide range of applications in chemical and pharmaceutical research. The company’s aim is to make flow chemistry easily accessible to both novices and experienced users.