Dairy Testing: Feeding Molecular Spectroscopy Demand

As with many sectors of the food market, the dairy and dairy product industry is evolving. A growing world population, rising standards of living in developing nations and increases in product variety are reshaping the industry. In addition, food safety issues and the industry’s need to increase productivity are influencing the requirements of dairy processors and producers. In 2018, milk output alone totaled 827 million tons, a 2.0% increase, according to the UN Food and Agriculture Organization. A 2018 report from the OECD stated that fresh dairy product consumption will increase 2.1% annually over the next 10 years, while consumption of processed dairy products will increase 1.9% annually.

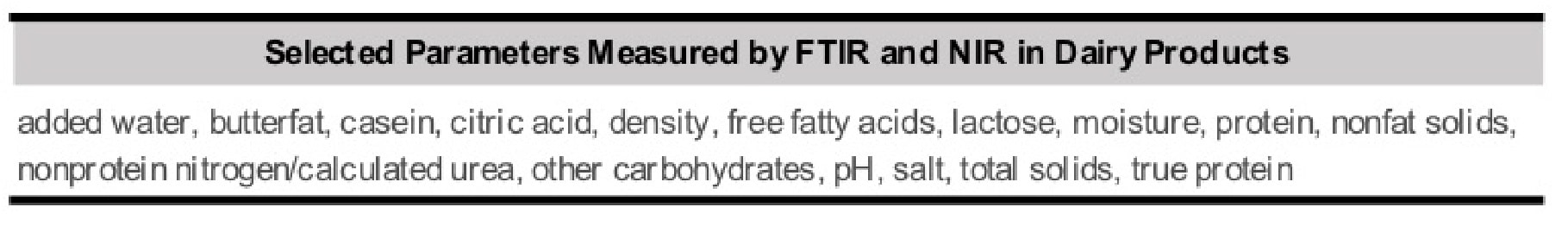

Molecular spectroscopy is widely used in dairy processing, particularly for QA/QC, where techniques such as FTIR and NIR rapidly and inexpensively screen milk to quantify compositional components, most prominently, protein, fat and total solids. Such techniques are non-destructive, require little to no sample preparation and can measure several components simultaneously. The interest in the market from molecular spectroscopy companies is evident by acquisitions in recent years and ongoing product innovation. As part of its expanding footprint in the food market, PerkinElmer acquired Perten Instruments in 2014 (see IBO 11/30/14) and Delta Instruments two years later (see IBO 2/29/16), both of which provide FTIR and NIR systems specifically made for dairy testing. Last year, Bruker added to its molecular spectroscopy offerings for dairy testing with the purchase of milk analyzer company Lactotronic (see IBO 7/15/18). Other companies providing dedicated milk testing systems include FOSS and Unity Scientific.

In this article, IBO examines what has made the QA/QC dairy testing end-market so attractive to molecular spectroscopy companies, finding that technology advances, new applications and novel product types are making testing more critical.

Improvements in the instruments themselves have enhanced the use of FTIR and NIR techniques for dairy QA/QC. Steve Holroyd, PhD, technical manager—Analytical, at Forterra, a global milk and dairy product company, highlighted for IBO improvements in the stability of different units of the same instrument from the same supplier. “Each instrument would give us a slightly unique result; similar but slightly unique,” he observed. “Over the last 10 years, we’ve seen a lot of progression toward the instruments being more similar to each other.” This has improved confidence in testing results. “A company like Fonterra, and this is true of any global key accounts that the vendors have, we have lots of instruments in different sites, and we want to know that they all go for the same result or very similar result.” He admits, “It’s not perfect. There’s still considerable room for improvement.”

Instrument Stability

The improvements in instrument stability have also enabled greater utilization and productivity for dairy processors through faster calibration and greater connectivity, according to marketing manager Dagmar Behmer, MarkNIR & Process Technology, Bruker Optics. “The more stable an instrument setup is (i.e., no drifting with temperature, more robustness in terms of vibrations, etc.), the more likely a calibration model set up on one instrument can be ported to other instruments of the same kind, even across different models without any modification. Here, systems utilizing cube corner interferometers have a distinct advantage.” These improvements have also enabled a higher degree of multi-instrument control. “Robust instruments are a prerequisite for universal calibration models. Part of our business is to develop calibration models, e.g., for the dairy industry, that can run with the same performance in a large network of FT-NIR instruments,” she explained.

Bruker provides FT-NIR and IR lab and process testing systems for dairy product QA/QC. “Bruker developed over the last years a unique portfolio—from standard IR analyzers for raw milk, processed milk and other basic liquid products, like skim milk, whey and cream, to sophisticated FT-NIR solutions for any liquid, semi-solid and solid samples,” noted Ms. Behmer. “Bruker’s MPA II-D FT-NIR spectrometer offers significant advantages compared to classical FT-MIR analyzers: It can measure liquid samples types even with higher viscosity like whey protein concentrates, infant formula liquid and sweetened condensed milk. With the same instrument setup, solid and semi-solid samples like milk powder, cheese, yogurt or butter can be analyzed. We believe to gain bigger market shares, thanks to this unique technology.”

Wopke Beukema, Dairy Market manager for PerkinElmer, attributes the greater instrument stability to changes in both hardware and software. “On hardware, the real breakthrough with FTIR spectroscopy came with the implementation of lasers (in the ‘80s) into the optical system to track mirror movement. Since then, there have been many improvements to optics quality, detectors and reductions in electronic noise.” PerkinElmer uses the same type of optics in all its IR dairy analyzers, explained Mr. Beukema. “Other hardware variations have been reduced to an absolute minimum. This is a great advantage with spectra among different types of instruments being shared and used for building better calibrations.”

Software

On the software side, and its impact on instrument stability, Mr. Beukema noted the changes in chemometrics and data processing made possible by faster computer processing speeds and the use of PCs. “As processor speeds have increased, so has the ability to perform more complex data analysis and calibration algorithms,” he noted. “These algorithms further help reduce ‘uninteresting’ sources of variation, such as instrument and sample matrix (i.e., natural variation of food products not associated with measurement of interest—protein, fat, etc.).”

PerkinElmer provides FTIR, MIR, FT-NIR, and NIR systems for dairy testing, including several dedicated systems, as part of the company’s wider offering of food analysis solutions. “With food regulations always on the rise and growing consumer awareness and demand around food safety, quality and nutrition, advanced food analysis is key for the dairy and food industry, and PerkinElmer has the technologies, software and services to help,” stated Mr. Beukema. “With Delta and Perten’s history in dairy, PerkinElmer is well-positioned to provide scientists and other testers/analyzers with specific features and applications for current and future dairy products.” The company’s dairy analysis products include Perten’s LactoScope FTIR Milk Analyzer and the PerkinElmer DairyGaurd FT-NIR system.

Software development has led to cost saving as well as greater automation, Dr. Holroyd observed. For example, he said, instead of individuals calibrating instruments separately in labs around the world, instrument calibration is now done remotely. “We’ve put in a lot of investment and work with the vendors on networking instruments together so we can support large networks of instruments. [This] saves a company like Fonterra a lot of money.”

In addition to improved networking and instrument control, other software developments are emerging. “Moving forward, the actual instrumentation itself will be an important component of required solutions, but only a component,” explained Mr. Beukema. “System integration (including on-line analyzers), data handling, data access, database management, material tracking, and rapid response support services and calibration/method development will all help molecular spectroscopy techniques to proliferate in dairy.”

Applications

Noting other areas of improvement in the use of FTIR and NIR for dairy QA/QC, Dr. Holroyd also cited cost of ownership and vendor support. “The vendors have put a lot of work into making sure [the instruments] don’t need a lot of maintenance, or if they do, the predictive maintenance is really up to scratch, so the instruments don’t break down or fall over—that [the vendors] should understand the performance of the instrument over a lifetime and how to adequately support it without putting a significant burden onto the customer.” These improvements also include instruments that are easier to maintain.

The greater stability and usability, and thus higher confidence in results, is even more important now, as the technology is being asked to do more complex applications, according to Dr. Holroyd. “[W]e’re increasingly using applications for these instruments that utilize much more of the spectral range of the instrument,” he explained. “Because we’re using lots of information, very small differences between the instruments can mean significant differences in results.”

Describing such an application, Dr. Holroyd explained, “Typically, they are new QA-type applications. So we might be looking at detecting, for example, something like food fraud.” Food fraud can take the form of adulteration, mislabeling and counterfeiting, among other types. “The addition of melamine to falsely augment protein in China in 2008 (see IBO 12/15/08) was a classic example, but the addition of water or other substances that appear to enhance milk fat or protein levels are all risks,” he said.

Mr. Beukema also highlighted the analysis of adulterants as an increasingly important application for compositional testing of dairy using FTIR and NIR. “[A]dulterants analysis is one of the fastest growing applications, as the conversation around food safety is increasingly in the public eye and driving more consumer education and awareness daily,” he noted. “The melamine issue in China is one example that readily comes to mind. Rapid and robust test solutions are important here to identify adulterants across the dairy product ecosystem.”

“Typically, the instruments have been designed for targeted applications in QA/QC, but as we roll out more and more non-targeted applications the requirements of the instrument are more stringent.”

Such an application is also an example of new types of non-targeted QA/QC analysis that are being implemented by dairy processors. “Typically, the instruments have been designed for targeted applications in QA/QC, but as we roll out more and more non-targeted applications the requirements of the instrument are more stringent,” explained Dr. Holroyd. “We collect liquid milk in 14 different countries and when you are looking at different geographies, each one has a different potential risk. So, I wouldn’t say we’re looking for specific things, but we’re really looking for something out of the ordinary. [W]e can identify what’s good and normal milk, and then we would set the application up that flags if something is somewhat abnormal.”

Another trend affecting food testing is the growing demand for dairy products in new regions. “Dairy products have globally become a very popular part of the diet. In the past, the demand was driven mainly by population growth and increased prosperity,” said Ms. Behmer. “Today, in addition, the milk and dairy consumption is rising fast in developing countries and also especially in Asia.” Demand from different regions as well as changing consumer preferences have resulted in new variations of dairy products. “With the growing amount of different products and recipes, a thorough quality control is essential to optimize plant efficiency and avoid costly recalls,” she added.

Among Ms. Behmer’s examples of regional changes is the greater consumption of cheese in Asia and the broader variety of products. “Today, more and more types of cheese get on the market with a wide range of compositions. Here the quality control with FT-NIR is ideal, since various recipes can be analyzed with the same set of calibrations,” she said.

Beyond changing regional consumption, responding to new consumer preferences has resulted in changes in the composition of dairy products that QA/QC testing must accommodate. This includes the addition of whey proteins to dairy products for nutritional enhancement. “We see a clear trend that whey proteins are today becoming increasingly popular as a general health trend beyond muscle growth and sports nutrition,” said Ms. Behmer. “FT-NIR offers an ideal solution for monitoring the liquid concentrates and the spray drying process, either directly online or offline in the production lab.”

She also listed growing diversification and specialization of recipes for infant formula as a trend. “Here, composition analysis during the process and final product testing is most essential,” she explained. “FT-NIR also has additional capabilities, e.g., the analysis of edible oils which can replace partly milk fat and, as a more recent trend, the quality control of fish oils such as omega-3 fatty acid additives to infant formula.”

Mr. Beukema also listed consumers’ increasing interest in health benefits as influencing dairy product composition and thus testing requirements. “We’re also seeing a growing need for different types of fatty acid analysis in the lab around health interests like Omega 3 and 6, as well as cow feeding approaches for de novo, mixed and preformed fatty acids.” FTIR and NIR analysis are used not only for final product control by processors but also for the analysis of raw milk by producers. “The ability to measure de novo fatty acids is helping farmers better manage their herds for both improved efficiency and output, as well as better animal welfare.”

Online Testing

Another trend, according to Mr. Beukema, is the use of online FTIR and NIR systems, in addition to testing in the lab or at-line, for dairy product QA/QC due to the goal of further guaranteeing product quality. “While online analysis is not yet widespread in dairy processing, it is a key goal and we’ll continue to see the industry moving towards it to help create continuous flow production,” he commented. “For example, real-time blending of milk streams to target fat levels is an important type of online analysis helping to create a more uniform, consistent final product. Likewise, real-time analysis of the spray drying processes for dairy powder production helps producers optimize drying times, thereby reducing energy use (which can be very costly) and providing a more consistent final product when it hits the shelves.”

“What we’ve found is that the number of instruments we’ve got has increased over time.”

Dr. Holroyd also noted the increase in online testing. “There is a trend towards some more online testing, but we’re still doing as much at-line, so the benchtop testing as we’ve always done.” Nonetheless, this has led the need for more instruments. “What we’ve found is that the number of instruments we’ve got has increased over time. We’ve kept the old ones that might be doing benchtop testing, and we’ve introduced new ones to do some online testing,” he said. Nonetheless, use of at-line testing is also rising. “But overall we have benchtop instruments doing more measurements at more phases of our processing.”

Ms. Behmer also expects an increasing need for online testing and accompanying technology improvements. “Due to the increasing production capacities and faster throughput, process control will become more important and we expect major investments in this field,” she said. “Here, the recent addition of dedicated probes for liquid dairy products and solids like milk and whey powders will strengthen our position in the market.” She added, “Overall, the dairy industry will gain more and more importance for our in-process business.”

Whether in the lab, at-line or online, the progress in FTIR and NIR’s use for dairy QA/QC is also evident in new international standards, according to Dr. Holroyd. “Those standards are really a very important part of global adoption of different ways of testing,” he noted. “There’s still a lot to do on that. The standards often lag the state of technology, but it’s an ongoing area of work.” He pointed to the International Dairy Federations’ (IDF) recently updated guidance for NIR in dairy products as an example.

Ms. Behmer also noted the impact of new standards, particularly for NIR. “The role of molecular spectroscopy in the dairy industry has grown substantially over the recent years. The capabilities were massively expanded by utilizing NIR for almost any kind of sample type, including raw milk and other liquid samples types in general,” she explained. “This was one of the reasons to update the ISO 21543 IDF 201 guideline for NIR, where Bruker took the lead of the project team, and which now covers all applied measurement options and product types.” New developments continue to enhance the technique’s recognition. This year, a new version of the standard will be released internally by the IDF, with ISO approval expected in 2019. “In addition, an IDF bulletin with a summary of various applications and sample types is close to release,” noted Ms. Behmer.

Summing up the attractive market for FTIR and NIR instrument in dairy testing, Mr. Beukema commented, “A demand for greater product diversity, efficiency improvements, further and stricter regulations and online analysis will all continue to drive growth here. The versatility, speed and ease-of-use of molecular spectroscopy is an ideal technique to meet many of these testing requirements in concert with classic IR and NIR techniques.”