RotaChrom Technologies Unveils Laboratory-Scale Chromatographic Method Development Platform

Revolutionary CPC Modeler Platform Promises Quick Method Development and Testing

Kecskemet, Hungary – RotaChrom® Technologies PLC proudly announces the launch of the CPC Modeler, a desktop-sized centrifugal partition chromatography (CPC) method-development platform. Known for its industrial-scale devices, RotaChrom has now expanded its portfolio to include a lab-scale device, designed specifically for researchers and laboratories. The CPC Modeler empowers researchers and laboratories to predict, test, and validate the most effective purification methods for a wide range of compounds of interest (CoI), including pharmaceutical APIs and natural extracts.

RotaChrom Technologies is known for developing the world’s first industrial-scale CPC platform. CPC is a liquid-liquid preparative chromatographic technique, in which separation occurs between two immiscible liquid solvent systems: acting as both the stationary and mobile phases. The liquid stationary phase is immobilized by a strong centrifugal force inside cells attached to a rotor, and the mobile phase is then pumped through the stationary phase in the form of tiny droplets. Separation of the injected sample is based on the sample component’s varying partition coefficients between the mobile and stationary phases.

CPC has several advantages like lower operational expenses, easy scalability, elimination of sample loss and irreversible adsorption, operation without silica gel or any solid stationary phase, and the possibility to separate a wide array of compounds.

“The CPC Modeler combines an in-silico method-development engine with semi-preparative chromatographic equipment,” said András Gáspár, Chief Executive Officer at RotaChrom. “Every part of the CPC Modeler, from software to hardware, has been designed to support research and preparative method development. Laboratories, researchers, and preparative chemists can use the platform to predict, test, validate scalable purification methods”.

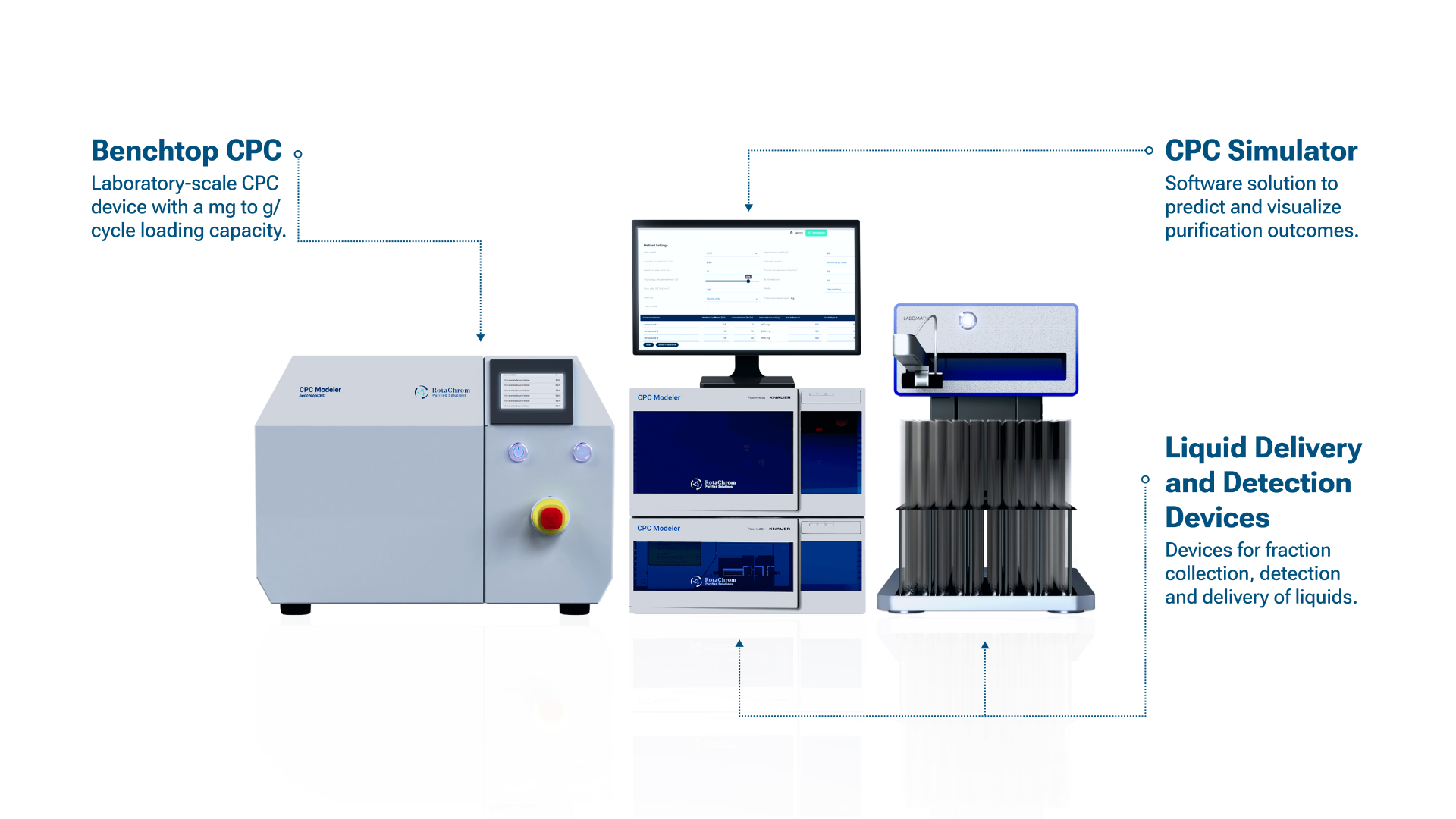

The CPC Modeler platform consists of three devices:

- The Benchtop CPC: A laboratory-scale CPC device with a mg to g/cycle loading capacity, 250 ml column capacity, and 5-50 ml flow rate.

- The CPC Simulator: Software solution to predict and visualize purification outcomes for a wide range of molecules in diverse suitable solvents systems.

- Liquid delivery and detection devices: Essential components for fraction collection, analysis, and liquid delivery.

The CPC Modeler’s cell geometry is optimized with Computational Fluid Dynamic (CFD) modelling to ensure effortless scale-up towards process scale for the method being developed on the platform.

The platform comes with an integrated GMP-compliant software suite and parallel the CPC Simulator tool, enables users to design and optimize purification methods in-silico before conducting live experiments. By leveraging a comprehensive digital library of scientific data and chemical compound information, researchers can streamline method development and accelerate the pace of discovery.

“With the CPC Modeler, researchers can customize and tailor the simulation to their purification setup and chromatographic device settings with confidence,” said László Óvári, Test Laboratory Manager. “By combining advanced simulation capabilities with real-world experimentation, our platform empowers scientists to achieve unprecedented levels of efficiency and productivity.”

The CPC Modeler, showcasing innovative engineering feats and a cell design capable of unique separation solutions, is supported by the robust liquid handling system device developed by Knauer. This partnership allowed the creation of a unique, cutting-edge, reliable, and industry leading platform.

About RotaChrom

RotaChrom Technologies develops and manufactures industrial-scale centrifugal partition chromatography (CPC) technology platforms. Founded in 2014 and located in Hungary, RotaChrom distributes its CPC devices around the world. With the help of their industry-leading chemists and engineers, their instruments revolutionized purification by providing cost-effective industrial-scale chromatography solutions to customers in various industries, including pharmaceutical, agrochemical, nutraceutical, and botanical extracts.

For more information about the CPC Modeler and RotaChrom Technologies, please visit https://hub.rotachrom.com/modeler